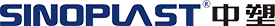

Analysis of the convection limited and conduction limited:

l In the case of external convection is limited, the lower heat conduction coefficient plastics can replace the aluminum radiator without increasing the temperature.

l In the case of heat conduction is limited, the higher heat conduction coefficient plastics can be significantly lower the temperature than common plastics.

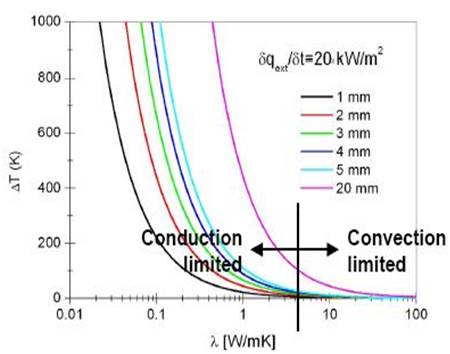

Comparison of radiator made by different materials

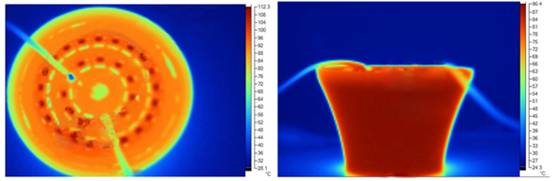

Test Report Ⅰ

Test environment:room temperature 25℃

Driving power:10W

Test condition:10*3 total 30PCS,3030 Al substrate

200mA constant current drive, 9761 RTV conductive adhesive

Test equipment:Fluke Ti10 IR tester

Test sample:A19 radiator

Test report Ⅱ

(Light source surface 85.5 ,welding spot 80.3, shell 77.4)

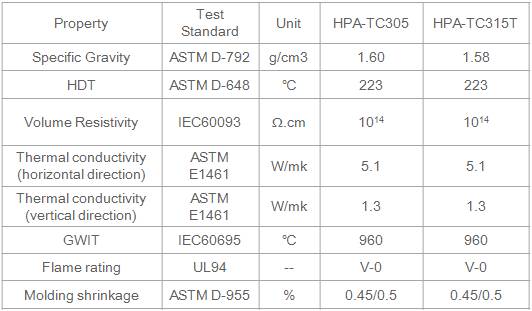

Technology parameters for LED radiating shell

Advantages compared with other thermal conductive materials

Anti-crack:-40 ℃ —120 ℃ ,30mins 1cycle,recycle 500hrs

Advantages compared with other thermal conductive materials

Grey color matching no mixed color:

Advantages compared with other thermal conductive materials

Yellowing resistant, anti-aging

Advantages compared with other thermal conductive materials

Laser etching

Advantages compared with other thermal conductive materials

Application example