NMT Technology Overview

Nano molding technology is a new technology to integrate the metal and plastic by injection molding. By this technique it realizes the hard resin components and sealing materials, packaging materials integrated molding, makes lightweight components.

NMT Technology advantages

Unlike traditional combination of metal and plastic, NMT technology is the combination of metal and plastic in the nano scale, with a higher binding force, while satisfy the requirements of the anode treatment of acid and alkali.

NMT technology in the product design does not only make the product have strong metal appearance texture, but also have the easy plasticity, can make the product towards the development direction of much lighter and lighter.

NMT technology in manufacturing greatly simplifies the process of production, improve the production efficiency.

As NMT is a safe and recyclable technology, so it is little impact on the environment.

Punching T treatment Injection Molding Post processing Boding with metal

The application of NMT material

NMT technology in product design is better than magnesium alloy and aluminum alloy die-casting products, has the very strong plasticity and the cohesive force.

NMT technology can be extended to a wide area, like digital camera, personal computer and mobile communication electronic products, etc.

Display cabinet Mobile communication products on-board computer panel

Sinoplast NMT material

Sinoplast NMT materials can be bonded with many metals, such as Mg, Cu, stainless steel, Ti, iron, red copper and so on. Has good resistance to acid and alkali, can be anodized, high temperature coating, precipitate free, plastic structure without drop, the main applicable materials include PBT, PPS.

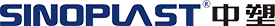

Standard test sample plate: Al: A5052 Resin: PBT, PPS

Tensile strength test

Sinoplast NMT material application examples